Electric Wire Rope Hoists

Electric wire rope hoists for loads up to 250T

VERLINDE has always been in the vanguard for innovative ideas and designs for lifting equipment (over 70 patents filed in France and world-wide). Its 170 years of experience which has enabled Verlinde to be the first company to develop the electric chain hoist.

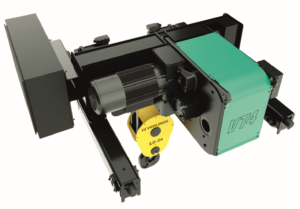

The new EUROBLOC VT electric wire rope hoist has been designed in this resolutely “avant garde” spirit – 13 patents have been approved from this design alone. Often copied but never equalled, the VT electric wire rope hoist offers a wide range of options making it practical for any applications. The tens of thousands of references around the world are testimony to the VT superiority and reliability.

“When investing in your production tool, you only want the best, that’s why you choose Verlinde”

The Verlinde range of Electric Wire Rope Hoists are designed to handle heavy duty loads up to 250T and offer fast lifting speeds. They are available without a trolley in a fixed mount installation or they can be configured for a low headroom operation, normal headroom or a double girder trolley configuration. A Wire Rope Hoist is the best solution for operations which require true vertical lift for precision lifting and accurate positioning of loads.

The Eurobloc VT Electric Wire Rope Hoist, is built to last. As standard, the VT offers the best the industry has to offer. High quality, compact, quiet and efficient, this hoist is packed with outstanding features.

- 2-speed hoisting motor (ratio 1-6) with bi-metal sensors. 60% operating factor

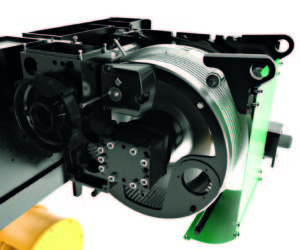

- Maintenance-free DC disc brake

- 4-position limit switch (up, down, high position deceleration, reversed phase protection)

- Load limiter

- Monitor MT2, supervisor unit for the hoist

- 3 to 20m/min variable speed travelling motor (lower load swing)

- Electrical cabinet with low voltage transformer and switchgear

- Safety on/off

- Standard 380V/400V/415V/50Hz, 440V/460V/60Hz power supply

- IP55 / Class F protection system for motors

- Tropicalised for travelling and lifting

- Cast iron rope guide for difficult environments

- Time counter

- Compact drum allowing best hook approach (C and F)

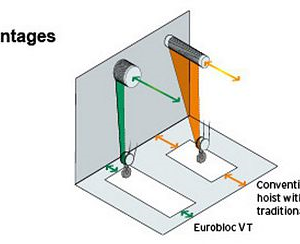

- Lower pulley lateral shift on lifting

For more information please download the product information and version PDF here

Safety

- Variable travelling speed for precise positioning of loads

- Wire rope is galvanized steel as a standard, high safety factor (factor 4,6 – FEM 2m)

- Electrical cubicle cover can be folded back so that you can store your tools for maintenance (the cover has two steel safety wires to prevent it from falling)

- MT2 electronic control of the recording of hoist solicitation status (as standard on VT4&5)

- MT3 electronic overload device and SWP calculation solicitation status (as standard on VT1,2&3)

- Low voltage control for more safety

- The 4 steering traverse wheels are fully streamlined for improved safety

- Rotating hook and pulley block with safety latch

Ergonomics

- Ergonomical hook (area to grab and hold)

- Push button box is made with tinted polypropylene, grounded, with double insulation, ergonomical (IP 65 protection). Optional load display available

- Electrical

cubicle is located on the side of the hoist, easily accessible. The open/close system uses a quick closure method

cubicle is located on the side of the hoist, easily accessible. The open/close system uses a quick closure method

Easy Maintenance

- Hoist motor cooling increased by 30% (tunnel effect)

- The hoisting brake is tested for hoist longevity under normal use conditions

- Steering reducer with one rail and a permanently lubricated connection

- The drum has been completely covered for better protection

- Rope guide is built “without a spring” so that it can be more easily replaced during maintenance

- Electrical cubicle wires go in and out by means of steel plugs that can be unbound and that are built into the case

- MT2 calculation of the SWP (Safe Working Period) deliver as standard on VT4&5

- MT3 calculation of the SWP (Safe Working Period delivered as standard on VT1,2 & 3. Assembly is in modules, for easier management of spare parts replacement

- Surface treatment is 2- component epoxy paint with 120 μ for greater protection

Savings

- Hoisting motor is 60% operating factor and tropicalised as a standard for greater longevity

- Travelling motor is tropicalised as a standard for greater longevity

- Pulley block is the best “C” dimension on the market for optimal use of the size of your buildings and optimal use of work areas

- Variable travelling speed to reduce wear on steering rollers

- Load limiter as ordered by the directive on “Machines” (required equipment). All EUROBLOC VTs are equipped with a load limiter as a standard (safety measure in the event of hoist overload). For greater longevity

- The hook and pulley block doesn’t take up much space, permanently lubricated rollers, pulleys are in GGG cast iron, very resistant. A high pulley/wire rope diameter ratio gives the wire rope greater longevity

Too numerous to list them all, the Eurobloc VT electric wire rope hoist offers a wide range of options to ensure you have the right solution for your lifting need.

- Explosion proof version

- VM Essential version (just the essential for limited budgets)

- Fix/ underhung/ low headroom/ double girder crabs available

- IP66 hoist

- Stainless steel hoist electrical cubicle IP55 or IP65

- Ultimate limit switches

- None standard rail width

- Higher traveling speed

- Radio remote control

- Travelling limit switch

- Derailment catches on double girder trolley

- Bogies trolley (only with HPN)

- Missing phase control

- Monitor 2 (MT3)

- 2 or 3 step overload device

- Overload device temporisation

- Optical and audible warning connected to overload limit switch

- Non standard main voltage

Rain cover

Rain cover- Horn on pendant box

- Explosion proof and / or spark proof version

- Load indication device

- Motors thermal protection

- Class H motors

- Heating device on motor

- Light in hoist panel